Investment Casting Temperature Sensor Boss

Delivery term:The date of payment from buyers deliver within days- Price:

Negotiable

- minimum:

- Total supply:

- Delivery term:

The date of payment from buyers deliver within days

- seat:

Zhejiang

- Validity to:

Long-term effective

- Last update:

2025-01-05 16:03

- Browse the number:

495

- Ningbo Suijin Machinery Technology Co., Ltd.

-

Contact:

nbsjcast(Mr.)

-

Email:

-

Telephone:

-

Phone:

-

Area:

Zhejiang

-

Address:

Yushantou, Dongqiao Town, Haishu area, Ningbo city, Zhejiang, China.

- Website: http://www.nbsjcast.com/ http://nbsjcast.stress-free-property.com/

By certification [File Integrity]

By certification [File Integrity]

Product details

What is Oxygen sensor boss?

An oxygen sensor boss refers to a threaded hole or boss on an exhaust system component, such as the exhaust manifold, catalytic converter, or exhaust pipe, where an oxygen sensor (also known as an O2 sensor) is installed. The boss provides a designated location for the oxygen sensor to be screwed in securely.

The oxygen sensor is an important component in modern automotive systems, as it measures the oxygen content in the exhaust gases. It helps the engine control unit (ECU) monitor and adjust the air-fuel mixture for optimal combustion efficiency and to reduce emissions. The oxygen sensor boss ensures proper positioning and attachment of the oxygen sensor to accurately measure the oxygen levels in the exhaust gases.

01 Part name

Oxygen sensor boss

02 Application

Automotive Industries

03 Material

Stainless steel

04 Process

Investment casting

& Machining

05 Casting method

Thermal Gravity Casting

06 Surface finished

As raw cast

(Shot blasting)

Part application-Auto industries

Investment castings for automotive applications require intricate structure, high precision, and reliable performance. Our services focus on high complex investment casting parts. We offer reliable and versatile parts manufacturing solutions to global automotive OEMs.

Engine system

Typical investment casting part we produce include:

1:ERG Housing

2:EGR Sensor Boss

3:Fuel Rail Bracket

4:Exhaust Inlet/outlet Cone

5:Fuel Injection Seat

Transmission system

Typical investment casting part we produce include:

1:Brake balance block

2:Shift sleeve

3:Balance weight

4:Connecting Rod

5:Pillow block

Chassis system

Typical investment casting part we produce include:

1: Square Bearing Housing

2: Steering Knuckles

3: Tie Rod

4: Starter Motor Cover

5: Brake Calipers

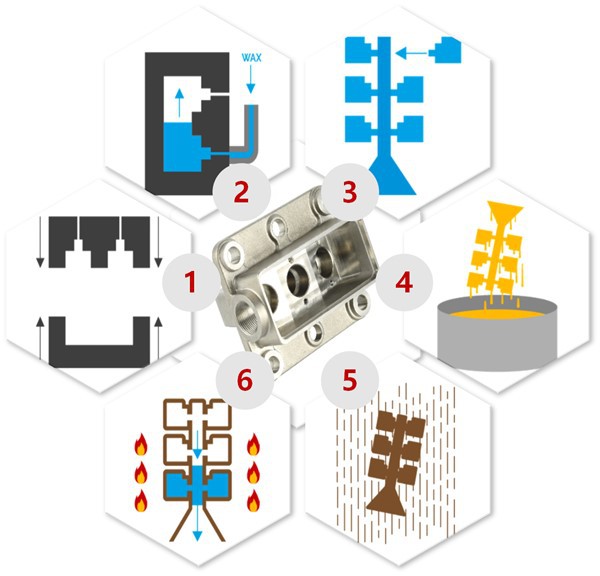

Production process introduce

1. Tooling Build

Design and building a metal die from Aluminum

2. Wax Injection

Injecting melted wax under high pressure into the cavity to get a pattern that replicates the finished part geometry

3. Wax Pattern Assembly

The wax patterns are assembled onto runners and into a finished tree which is ready to be dipped.

4. Slurry Coating

The assembly is then dipped into a high-grade ceramic slurry to build a ceramic shell around the wax tree.

5. Ceramic Shell build & Dry the shell

After the slurry coating is done, particles of sand are dropped onto the surface of the wet tree assembly. This helps to thicken and strengthen the layer of coating on the wax assembly surface, repeat 5-6 times.

6. De-waxing

Send the shell into pre-heating oven and then the wax inside the newly built shell is now removed. Dewaxing is done using a steam-dewaxing autoclave or flash fire furnace.

7. Melting & Pouring & cooling

Now the desired molten metal is poured into the pre-heated empty mold cavity, The mold then sits to allow the molten metal to cool and solidify which then becomes the final casting.

8. Shell Removal

The shell material is then removed through processes hammer knockout, vibration, and steel grit blasting

9. Cut-off

The finished parts are then cut free from the gating and runner system.

10. Grinding pouring gate

The ingate which remained after the sawing process, is grinded from the casting.

11. Final inspection

Once the finishing operations are done, the parts are inspected for surface and sub-surface defects.

12. Packaging & Delivery

For oversea shipping, we packaging with standard wooden pallet with size limited 1200*800mm

RFQ handle process

-

Get contact

You can find our contact info for further communication in "Contact US" column.

-

Send drawing

The 2&3D drawing format can be PDF, STEP, DWG, DXF and soon, can be sent via email. Wechat, WhatsApp, link.

-

Get quotation

After clear the demand of customer, we can send you the quotation with PDF format for documentation.

-

Sign NDA

For requirements for confidentiality of drawings, we can signed the NDA before you send drawing.

-

Finish feasibility study

The feasibility study of drawing is most key point to ensure the part can be fully meet drawing specifications, which is include material, dimension, surface treatment, and testing request.

Shipping and lead time

1

Delivery shipping port

The nearest shipping port is Ningbo port, the Port of Ningbo-Zhoushan is the busiest port in the world in terms of cargo tonnage. It handled 1.32 billion tons of cargo in last year.

2

Packaging solution

Normally we use the European standard pallet for oversea market, and also input the anti-rust bag for carbon steel parts for rust protection.

3

Available shipping method

We can support various shipping method, including sea shipping, air shipping, train shipping, and DHL, FedEx, TNT, UPS and so on.

4

Samples Leadtime

For CNC machining parts, the lead-time is about 5-10 days.

For casting and machining parts, it's about 25-30 days.

For casting and machining and surface treatment parts, about 30-40 days.

http://www.nbsjcast.com/

-

R32 Heating System for House

R32 Heating System for House

price: Negotiable

-

VAPME Crystal 7000 Puffs

VAPME Crystal 7000 Puffs

price: Negotiable

-

Oxalic Acid 25kg

Oxalic Acid 25kg

price: Negotiable

-

Edible Glucose

Edible Glucose

price: Negotiable

-

Stainless Steel Beer Mugs

Stainless Steel Beer Mugs

price: Negotiable

-

Antimony Impregnated Carbon Rod Blank for Making Carbon Bush

Antimony Impregnated Carbon Rod Blank for Making Carbon Bush

price: Negotiable